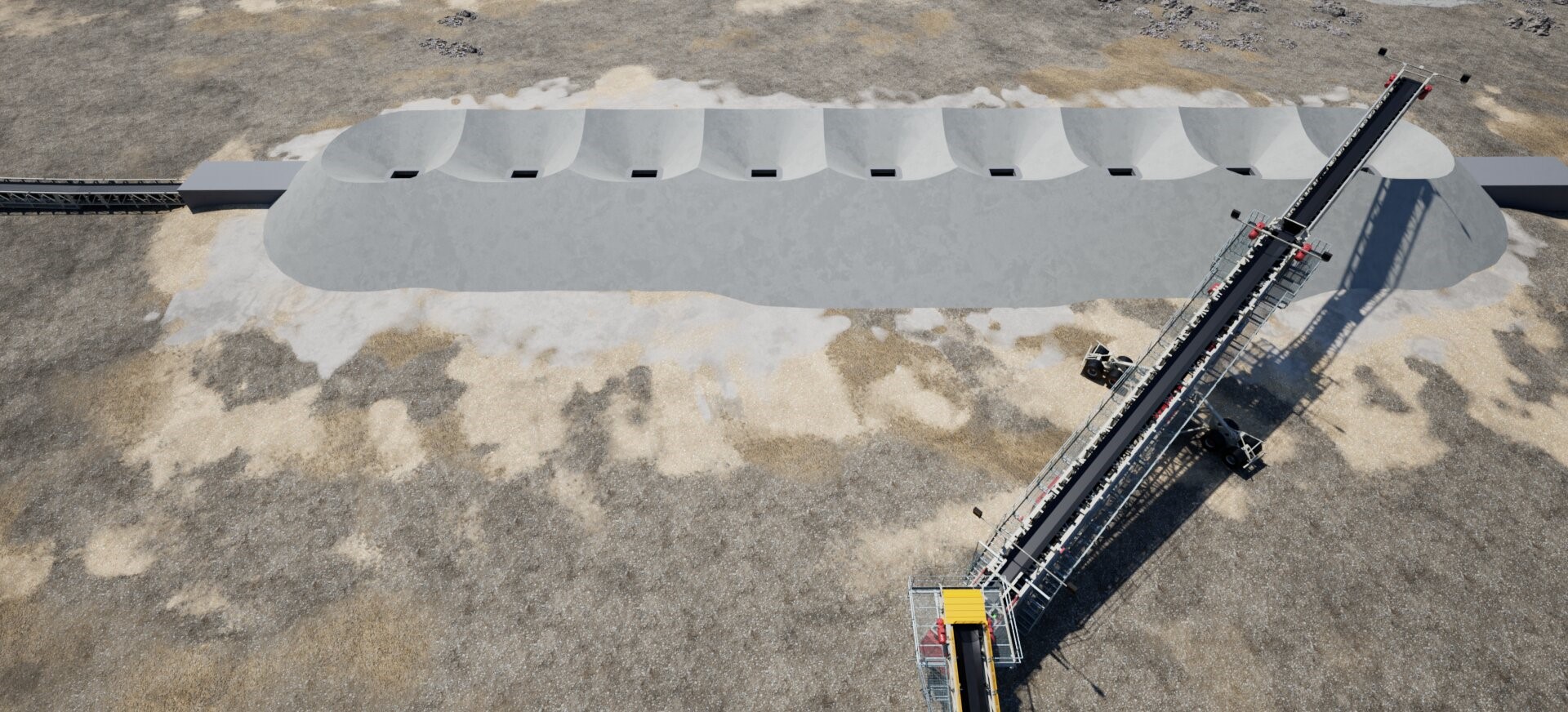

The Telescopic and Radial function enables the material to be stacked in a linear fashion, directly over the gravity reclaim feeders to maximise “𝒍𝒊𝒗𝒆” stockpiling drawdown capacity and minimise “𝒅𝒆𝒂𝒅” stockpile capacity.

The luffing facility enables a lower drop height, reducing segregation of the material. Therefore, giving a better blended distribution size of material being fed to downstream secondary crushing and screening equipment.

More accurate stacking of the blended material also reduces the risk of fine segregated material bridging over the reclaim feeders. Thus, negating the requirement of dozers and excavators to push “𝒅𝒆𝒂𝒅” material while improving site operational safety!

More accurate stacking of the blended material also reduces the risk of fine segregated material bridging over the reclaim feeders. Thus, negating the requirement of dozers and excavators to push “𝒅𝒆𝒂𝒅” material while improving site operational safety!

Typical fixed height primary surge pile stacking conveyors incur a lot of segregation and higher “𝒅𝒆𝒂𝒅” to “𝒍𝒊𝒗𝒆” stockpile capacity ratios.

Telestack can supply Radial Telescopic Conveyors up to 58-metre-long booms, enabling accurate placement to multiple reclaim feeders within a gravity reclaim tunnel application. Systems can be designed with communications protocol to link back to central control rooms via Ethernet of Profibus modules.

For any existing or new primary surge pile stacking applications, get in touch with us today and we will provide the solution!

Contact us >>> salesenquiries@telestack.com